5 Key Considerations When Selecting A Rigid Flex PCB Manufacturer For Prototyping

- Xpcb Pcb

- Jul 28, 2023

- 2 min read

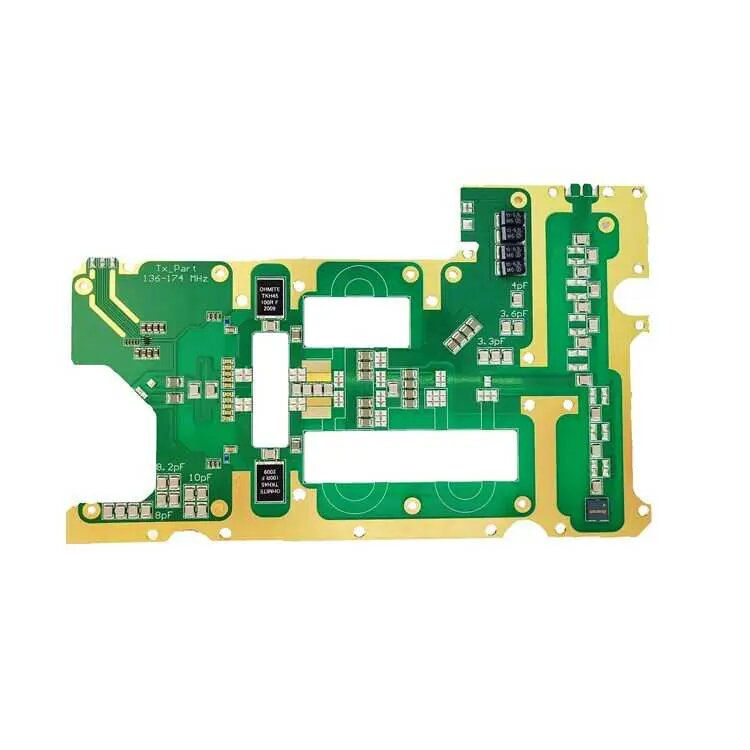

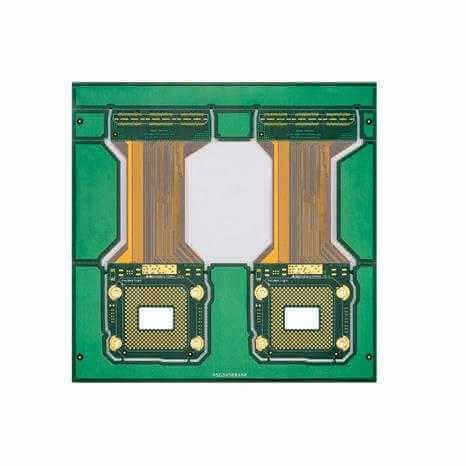

Selecting the right flex PCB manufacturer for your prototyping needs is crucial to ensure the successful realization of your designs. A reliable Rigid Flex PCB Manufacturer ensures high-quality prototypes, optimized designs, efficient manufacturing processes, and timely delivery, allowing you to bring your innovative ideas to life effectively.

The right choice of a flex PCB manufacturer for prototyping ensures that you receive prototypes that meet your specifications and performance requirements, setting the foundation for successful product development and minimizing the risk of costly redesigns or delays in the manufacturing process.

Here is what you should consider while looking for a manufacturer to handle your Flexible PCB Prototype project:

Experience & Expertise:

Look for a flex PCB manufacturer with a proven track record and extensive experience in prototyping. Their expertise in designing and manufacturing rigid-flex PCBs and Flexible PCB Prototype will ensure high-quality results that meet your specific prototyping needs.

2. Manufacturing Capabilities:

Evaluate the manufacturer’s manufacturing capabilities, including their equipment, technologies, and production capacity. A manufacturer equipped with advanced machinery and a well-established production process will be able to handle your prototyping requirements efficiently and deliver on time.

3. Quality Assurance:

Ensure that the manufacturer has stringent quality control measures in place. Look for certifications such as ISO 9001 to ensure that they adhere to international quality standards. Robust testing procedures, such as electrical testing and reliability testing, are essential to ensure the reliability and performance of your Flexible PCB Prototype.

4. Design Support & Collaboration:

Consider manufacturers who offer design support and collaboration services. Their expertise can help optimize your designs for manufacturability and cost-effectiveness. Look for open communication channels and a willingness to work closely with you throughout the prototyping process.

5. Cost & Pricing:

YES, the cost is an important consideration while searching for the right Rigid Flex PCB Manufacturer. Obtain detailed quotes from multiple manufacturers and compare their pricing structures. Consider factors such as quality, manufacturing capabilities, and design support to make an informed decision that offers the best value for your prototyping budget.

Conclusion

Carefully considering the experience, manufacturing capabilities, quality assurance, design support, and cost of a Rigid Flex PCB Manufacturer is essential for successful prototyping. By prioritizing these key considerations, you can make an informed decision and collaborate with a reliable manufacturer to bring your prototyping projects to fruition.

Comments