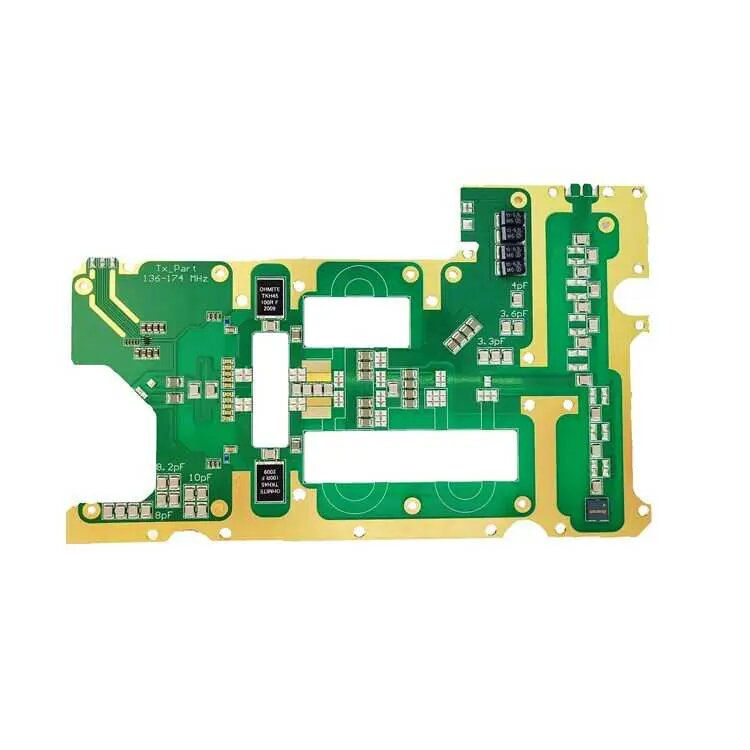

RO4350B PCB Manufacturing with All Features

- Xpcb Pcb

- Feb 23, 2023

- 2 min read

This high-frequency circuit board was created using the PCB materials that RO and the team collaborated to build. This business specializes in producing various laminates that are used in the production of PCBs. Also, Rogers PCB offers low electrical noise, low signal loss, high board temperatures, excellent performance, and cheap pricing. The cost of the RO4350BPCB manufacturer varies according to the manufacturer.

High-frequency

RO is the business that produces the laminate materials used in high-frequency circuit boards for high-performance devices. Almost all circuit boards are built of Flame Retardant Level 4 (FR4) materials, glass fiber composites, and epoxy laminated on one or both sides with copper foil. For the PCB, RO offers the FR-4 core with copper laminates, primarily to improve the frequency qualities of the roots. Features

Its tolerance and dielectric loss are incredibly low. In contrast to electrical qualities, it also possesses relatively steady frequencies. A Z-axis with little growth. It comes in either double or numerous layers. Excellent heat dissipation. Its primary copper comes in 1oZ and o.5OZ sizes. As per the RO4350B meets many PCB requirements. It highly resists oxidation. The SMT technique prevents soldering reflow and rework.

Application benefits

A high standard guarantees little electrical signal loss. It causes lower dielectric breakdown and low absorption of moisture. It has improved the control of thermal energy with various values for the dielectric constant. Space applications benefit from lower outgassing. It has higher-level impedance control. RF circuit boards-friendly and highly dependable, and accessible for application in significant industries. The practicality of use in mobile networking and aircraft is ensured by high frequency.

Constructing Guidelines

Different pinless and pinned tooling systems are compatible with the RO4350B. As a result, this decision is based on the preferences and capabilities of the circuit as well as the needs of the final registration. When working with the thinner cores, apply chemical processing. Use mechanical processing for the thicker roots. This is because numerous thermosetting and thermoplastic adhesive techniques are compatible with the Rogers 4350B laminate.

For More information Visit us:: https://www.x-pcb.com/product/4-layer-rf-pcb-manufacturer/

Blaze

Comments